Vieille Montagne headquarters – Angleur- Belgium circa 1855 ( lithography from A.Maugendre watercolor painting)

Vieille Montagne History at a glance

The point of view of Jean Jacques DONY

The following text written by R.Baltus was performed by a comedian at the 180th anniversary of the Vieille Montagne Company at the reception room of the Intercontinental Hôtel in Paris on Oct 13th 2017 !

« What a gathering! So many important people here this evening! …How tremendously proud I am! Of course, I had to come back for a few hours….

My name is Dony, Jean Jacques Daniel Dony. As you have guessed, I am an abbot … I served God but I’ve dedicated my life to zinc. Zinc is my life! Ever since I was a child, I’ve loved chemistry….more than sermons! So, I developed a unique process to reduce calamine, a mineral rich in lead and zinc, into metal. Nobody had managed to do this before me. Nobody… Pure zinc, so pure, it’s my life work!

And the Altenberg mine, on the borders of the Empire, what a blessing! Who could have imagined such a concentration of these wonderful metals? Yes, I am the Vieille Montagne pioneer!

It was I who convinced the Emperor to take care of that rich mine, of the fabulous material, the fledgling industry… It was I!

But I’m an inventor, not a manager….. and never would I have imagined all the successes you have known after my death in 1819. From up there, I have been observing you all, warmheartedly, I love what you have done with my zinc, my heirs…

First of all there was François Dominique Mosselman… he’s the one who bought my patents and my plants. But he sure knew how to get sthings off the ground! Zinc panels and roofing. He knew it would work… And he had a daughter, so beautiful and so intelligent that she married a count, who became an ambassador in Paris

Ah Fanny, Fanny Mosselman, the ambassador’s wife with her golden hair. In fact she was more of an ambassadress for zinc than she was of Belgium!

They were clever those Mosselman, they knew who to mix with…..And they chose their directors so well: Charles de Brouckère, the visionary Louis-Alexandre de Sincay and his valiant son Gaston…. Such exceptional men who led the company for more than 8 decades and made the Vieille Montagne the first multinational in the world!

And sometimes Vieille Montagne’s history crossed paths with the great History of France!

The shrewd and brilliant Duke, Charles de Morny fell head over heels in love with Fanny Mosselman, and Fanny funded, from the Vieille Montagne budget, his political and industrial career. The Duke de Morny, could then plot and organise the famous coup d’état which made his half-brother, Napoléon III, the Emperor of France.

Yes, the Second Empire owes a lot to Vieille Montagne…..and the Empire gave it a lot in return….

Napoléon III appointed baron Haussmann Prefect of Paris to completely restructure the city. And it was the baron who imposed the Mansard roof, and my zinc to cover all the roofs of Paris, and to collect rainwater…an ocean of Vieille Montagne zinc….

Then there were the Great Exhibitions, the wonderful buildings that are part of France’s heritage, the Grand Palais, the Gare d’Orsay, Les Halles de Paris and all those buildings in all the major cities that were influenced by Paris: London, St Petersburg, Buenos Aires….

But also the disasters of the two World Wars, when zinc became a strategic metal…

1945. After the plants were destroyed…well, they were rebuilt, even bigger and even more modern, and they made the most of it to innovate…Oh yes! They really know how to innovate at VM. Because not only were there great leaders, there were also great engineers who always knew how to bounce back…..and thanks to them, Vieille Montagne was always one- step-ahead. Just like today!

More recently, I was quite moved when Vieille Montagne was integrated into large groups such as Union Minière and Umicore. Once again, there were great directors who had a vision for the future…. Jean Pierre Rodier, Karel Vinck, Thomas Leysen and recently Marc Grynberg…(there were always those who held the torch high for the company’s culture, its pride and the two famous letters V and M …)

Ah! my friends, from up there I watched the Vieille Montagne saga like a film that kept me on the edge of my seat. Not even the best of scriptwriters could have imagined a more wonderful, more spectacular story… a story of love and passion between a material and men. The story of a community that lives on today.

My invention is over 200 years old. VMZINC was officially created in 1837. This means it is 180 years old now. !

I wanted to check for myself if the soul was still there…. So I took my pilgrim’s staff and discreetly toured the plants and commercial representations. I heard many different languages being spoken, so I didn’t understand everything, but I did hear that they celebrated in style and filmed all the festivities…

But enough from me, I’ve been talking a lot and I can see you’d like to get on with the rest of your meal. I am just a ghost who lives on memories, but also on the future. I can’t wait to see what comes next!”

I was very happy to meet you, it’s been a great honour…it’s such a great honour for the modest person I’m….such a great honour! »

Local history

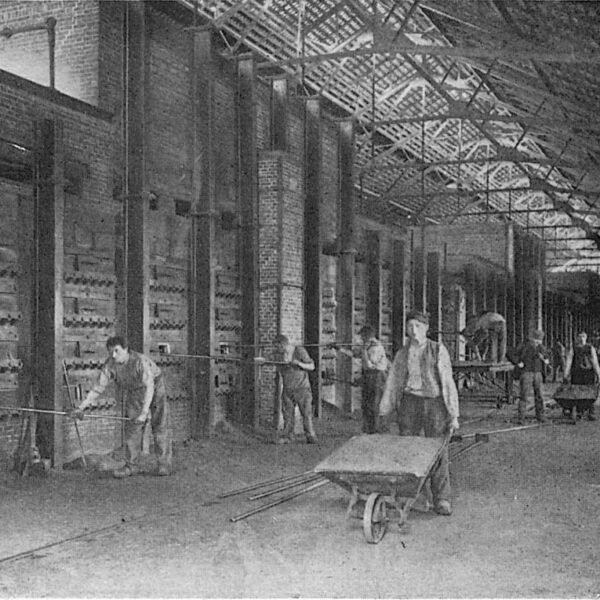

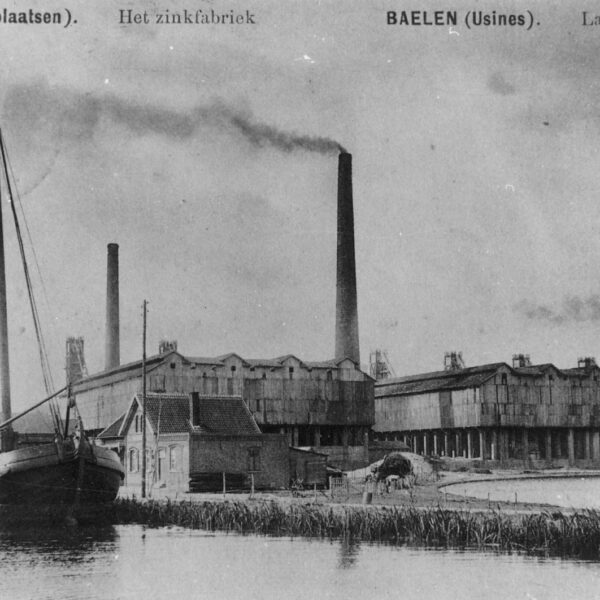

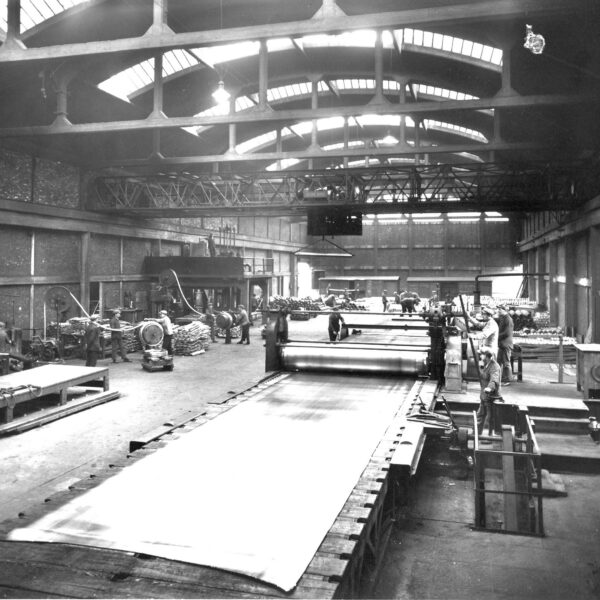

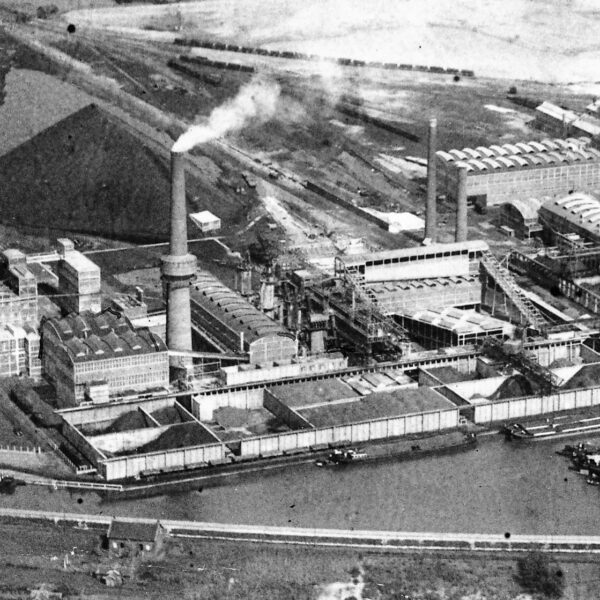

View of the VM Balen factory dated 1902 – photo-montage by F.Wouters – VM photographs found - ULiege

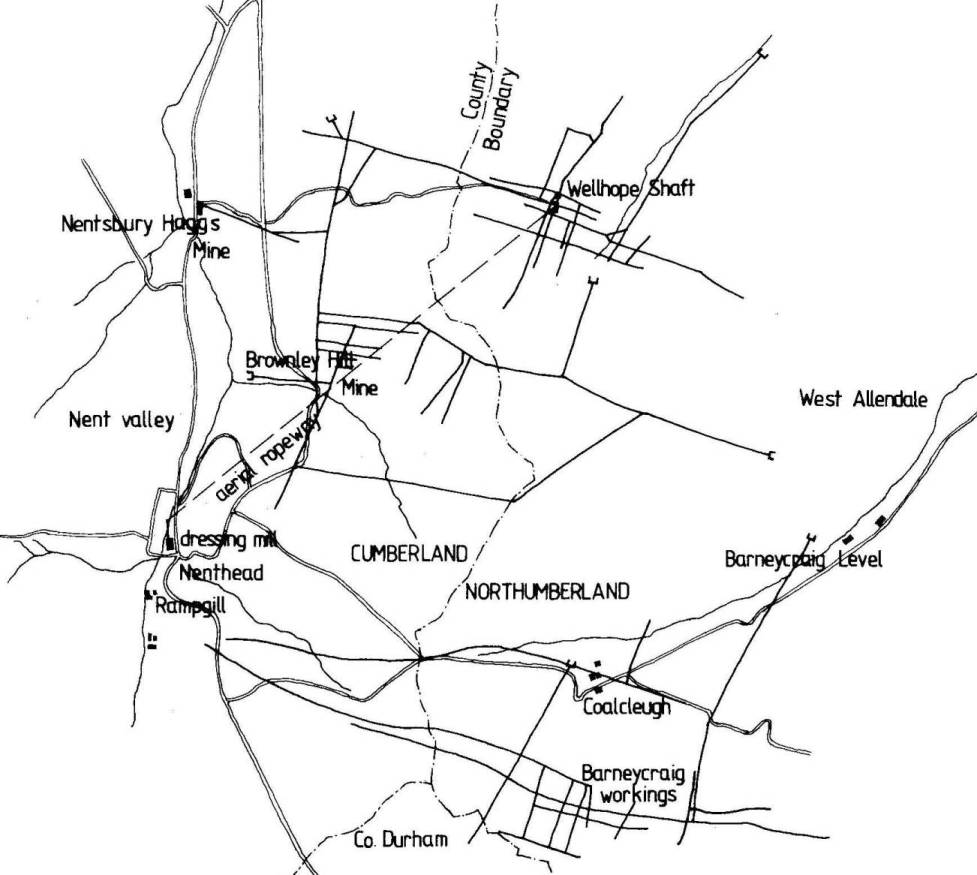

1. The Vieille Montagne Zinc Mining Company of Belgium on Alston Moor UK

The Societe des Mines et Fonderies de Zinc de la Vieille Montagne company of Belgium, or ‘VM’ for short, came to England in 1896, specifically to the small remote village of Nenthead in the Pennine hills of Cumbria. While in England, this international company survived two world wars and the inter-war economic depression, as well as fluctuations in the geological supply and market demand for zinc and lead. Then in 1949, after fifty-three years of operation, the VM sold its mineral leases, plant and equipment and left.

From Roman times until the end of the nineteenth century Alston Moor in Cumbria was famed for the production of lead. For over 180 years from the early 1700’s the leading exponent was the London Lead Company with smaller, locally-based enterprises operating throughout the same period. The industry went into steep decline from the 1860’s onwards due to the decreasing ore reserves, the cost of extraction and foreign competition. In 1882 the London Lead Company sold its interests to the Nenthead and Tynedale Lead and Zinc Company. After initial success, a sharp decrease in the value of zinc and the Earl of Carlisle’s refusal to renew the company’s lease of the spelter works at Tindale Fell, fourteen miles away, led to the company’s failure after a tenure of only fourteen years. The new purchaser of the mineral leases, mines, royalties, mills, works and machinery on Alston Moor in 1896 was the Societe Anonyme des Mines et Fonderies de Zinc de la Vieille-Montagne of Belgium, or VM for short.

From its mines in Nenthead and West Allendale the company obtained zinc ore by mining and by reprocessing old waste dumps from former lead ore extraction, at one time producing 60% of the UK output. In addition, although zinc was the main mineral the company was seeking, any lead found was not discarded, but processed as well. Both ores were not spelted (for zinc) or smelted (for lead), instead they were sorted, crushed and cleaned at Rampgill Mill in Nenthead, then transported by road, rail and sea to the parent plant in Belgium. This was the practice of the company with its mines worldwide.

The establishment of the Vieille Montagne Company at Nenthead was the start of an era of new technology, when previous methods and techniques were replaced by a new dynamism backed by huge financial investment. The VM invested many hundreds of thousands of pounds in the area, it was at the forefront of mining and ore processing technology in Britain and Europe, attracting visitors to the village from a distance to view its plant, it employed hundreds of men of several nationalities, mainly Belgian, German and Italian, and the local economy depended on its success.

In this region of the North Pennines the London Lead Company is rightly famous, revered and written about, but little is known about the Vieille Montagne Zinc Company of Belgium. The proposed anniversary weekend aims to redress the balance in order to promote national and international recognition for the company.

2. The story of Vieille Montagne in Sardinia

In 1864-65 a Belgian engineer called Eyquem discovered Europe’s largest calamine ore deposit called Malfidano in a place called Buggerru (Sardinia SW). The news spread throughout Europe and many mining companies came to Sardinia to undertake the mining activity.

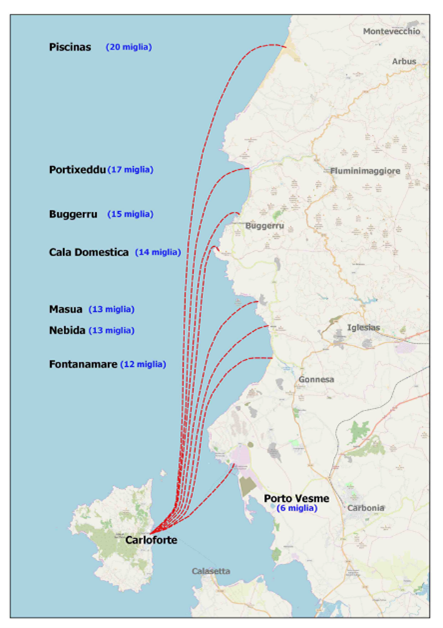

Vieille Montagne arrived in Sardinia in 1865 with a series of technicians who, in the first years of their stay, studied the minerals market, who produced lead and zinc ores, the quality and seriousness of these companies. The technicians checked and purchased batches of galena and calamine, which were then shipped by steamship from Carloforte, located in the Saint Peter isle in the SW of Sardinia, to Anversa /Anvers (from 1871 VM started to use the Sete’s harbor located near Marsiglia /Marseille, because it was closer to Sardinia). From there the ore arrived to the smelters (Liegi-Liège – Angleur – Saint Leonard) and Viviez and Penchot in the south France.

At the end of the 19th century, Engineer Cappa, Sardinia’s Agency VM director, decided to make an assessment of the minerals shipped from the Sardinian harbours of Cagliari and Carloforte to VM’s North Europe smelters.

In the 28 Settembre 1871 a joint venture was signed in Paris between VM and Sociètè Civile d’Iglesias (Ernest Garnier – Elisabeth Laumand owners)) . The contract stipulated that Vieille Montagne was going to allowed to work in the following mines for 50 years : 1-Sa Duchessa. 2-Monte Agruxau. 3-Monte Cani. – 4-Ghirisonis e Tiriarguis 5-Cungiaus Canonico Lai 6-Cungiaus Perdas Biancas – 7-Genna Maiori e S’acqua Fridda – 8-Bega sa Cruxi

On the same day, the Garniers signed the promise to sell to VM the factories in Penchot and Viviez in the south of France and the calcination plants they owned in Carloforte.

The April 4th 1872, VM bought from Petin, Pion, Gouin Company the existing Mining concessions and Plants of Saint Benedetto and Coremò.

From 1913 to 1920 VM bought in the Masua area two mining licences: Acquaresi mine from United Mines Limited (owned by Pertusola) and Masua mine from the Lanusei mining company. VM had to decide how to transport all the ore it produced and in this regard there were two proposals for where to build an ore port :

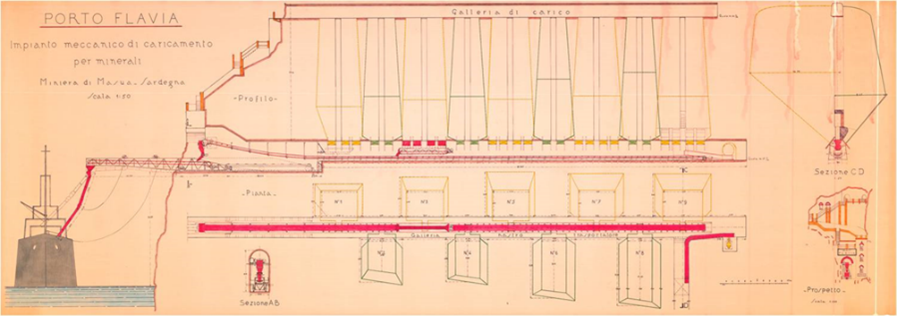

The VM company decided to build the plant in “Bega Sa Canna Area”: (red color place). Ing. Vecelli was commissioned by VM to build an ore loading plant at “Bega Sa Canna area” :

“Affaires de Sardaigne. Création d’un port à Bega Sa Canna: Le conseil se rallie à la proposition de la direction générale concernant l’installation d’un port à Bega Sa Canna et vote un crédit d’environ 1.000.000 de lires (550.000 frs) à dépenser en trois ans et à amortir en cinq ans, si l’exploitation des mines est remise en activité” (Archives de l’Etat a Liège – Vieille Montagne).

The plant was build from 1922 to 1924 and starting to work from 1925. The cost to build this plant was about £ 1700. The company dug 9 silos between the two galleries (upper gallery dig at +37 mls and the lower gallery dig at + 16 mls, with a capacity of 10.000 tonn.

The upper tunnel was 600 metres long and was excavated in six months, the lower tunnel was 100 metres long and was excavated in three months. The lower tunnel was equipped by a transporter belt located along the entire stretch. This conveyed the ore discharged from the silos located between the two tunnels to a moving lever arm that protruded 15 metres out of the mountain. At the end of the moving arm was a rubber tube that was directed into the ship’s holds.

The potential of the plant was 400 ton/hour, but it was preferred to operate with 200 ton/hour to avoid blockages inside the silos.

The plant worked from 1925 until the early 1960s, only to be closed: it became obsolete and the company preferred to transport the minerals to the smelters by truck.

THE FALL OF VM IN ITALY

At the outbreak of the second war world the Iglesiente and bergamasco agencies, were unable to comunicate directly with the general officies of Liegi. In 1940 Belgium got invaded by the nazy, Italy joined army with the germans.

In the same year the Italian government issued a prefectural decree taking away the licences of the mines in Italy from VM and transferring them to an Italian company called A.M.M.I.

In order to stay in Italy, VM agreed to make a partnership with the Italian company A.M.M.I where VM was a minority shareholder

In April 1947 VM ceded to A.M.M.I. its shares and in return it obtained 9350 tons of calamine at 48%.

June 10th, 1948 with the transfer of VM shares to SAPEZ (A.M.M.I Group), closed the chapter of its activity in Italy!

Dott. Geol. Mauro Buosi

mauro_buosi@alice.it

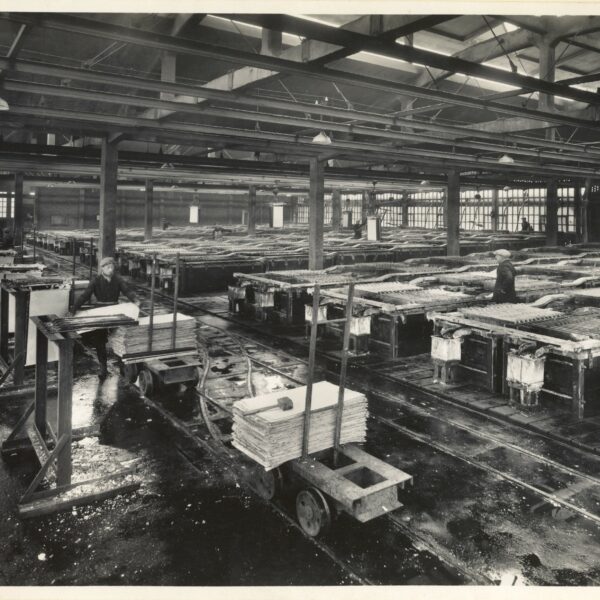

3. From zinc ore roaster and lead smelter to zinc smelter, the story of Vieille Montagne in Balen (B)

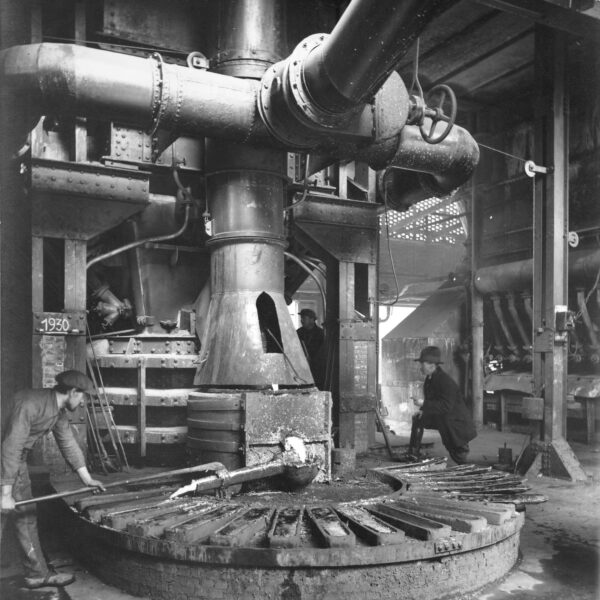

At the end of 1888, Vieille-Montagne purchased a terrain of 365 hectares on the borders of Balen, Mol and Lommel. The factory in Balen (then Baelen) was built in 1889 on the sandy grounds of the Campine. Ideally located at the intersection of the Antwerp-München-Gladbach railway and a branch of the “Kempens” Canal that connected Antwerp, the port of entry for the ores, and Liège, the final destination of the roasted ores. The factory itself was built by Gustave Ross, a German engineer, who used his knowledge in the Vieille-Montagne roasting plant in Oberhausen to develop a roasting unit for zinc blende in Balen. At the beginning there were 20 hand-operated roast furnaces for blende that released their gasses in the open air with a catastrophic effect on the environment.

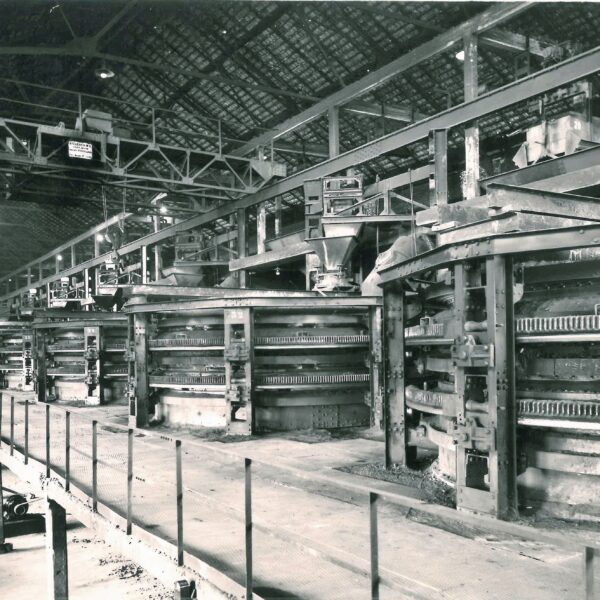

1908 New roasting plant Vieille-Montagne in Balen.

The zinc industry in Liège originated in Moresnet in the early nineteenth century. In the Moresnet area you found the Altenberg (Vieille-Montagne) zinc mine in Kelmis (La Calamine). The zinc ore calamine was a mix of smithsonite, hemimorphite and willemite. Zinc was recovered from roasted calamine by reduction. After 1860, when the Altenberg mine was exhausted, the production of calamine in Belgium fell sharply and Vieille-Montagne was forced to switch to zinc sulphide. Zinc sulphide, also called blende, was found in the mines in the Moresnet concession. VM also owned an important mine for zinc blende in Sweden. Both the calamine and the blende had to be roasted before they could be processed into zinc in the reduction kilns. At that time, zinc was produced exclusively by reduction.

During the process of roasting zinc sulphide, sulfuric fumes are released, which heavily pollute the environment. For environmental reasons Vieille-Montagne started looking for a sparsely populated area. This was found in Belgium in the Antwerp Campine on the border with Limburg. Here they bought a site of more than 387 Ha. The plant installations covered about 9 hectares.

At that time there was already roasting in Flône, Oberhausen and Ammeberg. But the production capacity turned out to be insufficient and that’s why they chose to build a fourth roasting unit in Balen.